FAQ of BMW Diagnostics and Programming [Real Users]

Here are a FAQ of BMW diagnostics and programming issues, quoted from http://www.bimmerforums.com/forum/ including the following parts:

1.BMW diagnostic tools

2.Alternator Diagnostics

3.Brake Flush and Bleed Procedure

4.Check Engine Light

5.Coolant Changes and Checks

6.Coolant Loss and Head Gasket Check

7.Cooling System Bleed Procedure

8.Cooling System Flush

9.M Series Engine Air/Fuel Ratio, Idle, and Misfire Issues

10.M Series Engine Cooling system Maintenance

11.Parking Brake Adjustments

1.How to choose a proper BMW diagnostic tool

Full diagnostic and programming for all BMWs: BMW ICOM A2+B+C emulator (BEST)

BMW E series coding: K+DCAN inpa USB cable

BMW F series coding: ENET cable

BMW motorcycle troubleshooting: ICOM A2 + ICOM D, K+DCAN adapter + ICOM D

Tools depend on models and functions to be realized!

2.Alternator Diagnostics

A simple DIY test of the alternator can be done with a DMM. This may not work on N series engines (see below), but you can try. At idle you should see about 13.5v and you should see about 14v at 2500rpm. The 2500rpm reading should not drop much if you load the system by turning on the headlights and the HVAC blower to high. If you don’t see those voltages the alternator isn’t working correctly.

In many cases the cause will be worn brushes in the regulator/brush assembly. If the alternator bearings are in good condition a new regulator/brush assembly may be all that is needed.

If you remove the alternator belt, you can check the condition of the bearings. If the bearings are really bad, that will be apparent. But that isn’t necessarily a conclusive test as the alternator bearings won’t be under load. The regulator can be replaced without removing the alternator from the car in many cases on the older cars. When removing the belt you must loosen the pivot bolt at the bottom of the alternator. The top adjustment/lock is obvious, but if you don’t loosen the pivot bolt you’ll damage the adjuster (it it already hasn’t been damaged). If the adjuster is inop, a pry bar can be used to set belt tension.

On an E30 another possible problem that will prevent the alternator from working is the battery warning light in the cluster. If that bulb is burned out (doesn’t come on when the ignition is switched on) it won’t supply exciter power to the alternator and thus the alternator won’t charge. At some point in the production run a resistor was added in parallel to the bulb to avoid a burned out bulb from preventing the alternator from working. But I don’t know when that happened.

If you have to replace the alternator, do not get a generic reman (cheap) unit. Those have been known to not work out-of-the box or fail shortly after installation. Use only a genuine factory rebuilt unit. It will cost more, but it will work out of the box and likely work for a long time.

There is an immense difference with the latest cars. The alternator output is controlled entirely by the DME, and fuel-saving strategies built in by the factory. These strategies prevent the alternator from charging, in many instances, UNLESS THE CAR IS COASTING! that’s freaky….but here’s a link: (Scroll down, it’s there)

http://www.roadandtrack.com/car-cult…ns-bmw-n63-v8/

As an FYI (from bmwdirtracer), the first sign of failing bearings on E46 gen cars can often be the red rust stains on and around the alternator. This hasn’t been observed too much on older cars than E46/E38/E53

Also as an FYI, some battery info:

%chg Voltage S/G

100 12.7 1.265

75 12.4 1.225

50 12.2 1.190

25 12.0 1.155

0 11.9 1.120

Sulfation of batteries starts when specific gravity falls below 1.225 or voltage measures less than 12.4. Sulfation hardens the battery plates reducing and eventually destroys the ability of the battery to take and hold a charge.

Only 30% of batteries sold today reach the 48-month mark. In fact 80% of all battery failure is related to sulfation build-up. This build up occurs when the sulfur molecules in the electrolyte (battery acid) become so deeply discharged that they begin to coat the battery’s lead plates. Before long the plates become so coated that the battery dies.

In the general case (except for N series cars) you can figure on 6 years as being the useful life of a battery, even if it has never suffered from deep discharges.

3.Brake Flush and Bleed Procedure

Usually it is best do a flush and bleed at the same time as the fluid is to be changed every two years. Unless you are meticulous in keeping maintenance records, put a sticker on the reservoir showing the date of the last fluid change.

A pressure bleeder, which isn’t expensive, makes this an easy one person job. One liter of ATE Type 200 fluid is more than enough for a full flush/bleed on a car with a three channel ABS. You will need about 1.5 liters on later cars with the four channel ABS system.

The ATE fluid has proved to be resistant to moisture absorption, by testing. Which means that there is little chance of rusting or boiling of the fluid under hard braking conditions on the street.. It also has a reasonable boiling point which may be enough for lower powered cars to make it suitable for track/race use. To be really safe on track, use Castrol SRF it has much higher boiling points, though it is expensive and needs to be changed at least once a year. Don’t overfill the reservoir, especially if the car will see the track.

The process goes like:

Start by sucking the old fluid out of the reservoir (a turkey baster works or large syringe). Then connect the filled bleeder and pump it up to about 15psi.

On early cars with the three channel ABS system, push a measured 200cc of fluid through each rear caliper and a measured 150cc through each front caliper. Push a measured 100cc through the clutch system on a manual transmission car.

On later cars with the four channel ABS system, push a measured 350cc of fluid through each rear caliper and a measured 150cc through each front caliper. Push a measured 100cc through the clutch system on a manual transmission car.

It doesn’t matter which rear wheel you start with, but the last caliper should be the left front. When the flush/bleed is finished, turn the bleeder upside down and drain fluid from the bleeder to fill the line on the reservoir and clear the hose of fluid. Then when you remove the cap from the reservoir you won’t have fluid spraying out and making a mess.

Toss any left over fluid to avoid taking a chance on it absorbing moisture. If the brake & clutch system has no leaks you will never have to top up the system and thus have no use for the left over fluid.

If you do spill brake fluid, wipe it up and then clean with water, or better yet spray on something like Simple Green and wash that off with water. Brake fluid will eat up paint.

A failure to bleed a caliper could be a plugged bleed nipple, a collapsed soft line, a pinched hard line, a bad master cylinder, or a stuck valve in the ABS unit. Cracking the line at the ABS (input and output) unit will tell where to look next. In a like manner cracking the soft line where it mates to the body lines and the caliper will narrow the search area.

The brake master cylinder has a section for the front brakes and a section for the rear brakes. So it becomes a suspect if neither rear caliper will bleed or neither front caliper will bleed.

4.Check Engine Light

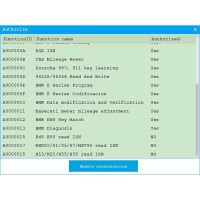

If the Check Engine Light (CEL) is, or has been, on there will be stored codes pointing to what is wrong. It is critically important that these codes be read with the proper diagnostic system. That means a dealer or very well equipped BMW indie shop. The entire car needs to be scanned, especially on later cars as there are a lot of electronics and they interact. Examples of proper diagnostic systems would include:

BMW’s DIS/TIS (“GT-1”)… (’07 and older)

BMW’s newer systems, known by various names: ISIS, ISTA and ICOM

BMW’s INPA

Autologic

SnapOn systems with the proper BMW S/W

Matco Launch with the proper BMW S/W

Understand that the fault codes are not necessarily to be taken literally. In many cases a particular fault code just tells you what the car is unhappy about, not necessarily what the real cause is. And that is where the experience and skills of a pro are important in interpreting what the codes could mean.

While P codes below 1000 are federally mandated, the codes above that are left to the vehicle manufacturer to define. They frequently vary by model, year, and engine. BMW diagnostic systems don’t use P codes, but the generic OBD do. Generic OBD code readers can’t scan everything and they frequently produce invalid or misleading results because they don’t have tables for the variants in codes for the various model, year, and engine. So that is usually a meaningless exercise.

In states that require emissions testing it isn’t uncommon for part of the test to include a scan for codes. In that case the car will fail if any codes are found. Which means that the fault(s) must be fixed, the DME cleared of codes, and the car driven long enough for the DME to go “ready” which requires that all of the conditions of the “Federal Test Procedure (FTP) Driving Cycle” have been satisfied. The car won’t pass testing until the DME is in a “ready” state.

5.Coolant Changes and Checks

Over the years BMW has changed the replacement interval for coolant from every 2 years to every 4 years. You should replace the coolant according to what your owners manual calls out unless it states that the car has lifetime coolant as some of the latest cars call out. In that case don’t go beyond 4 years on coolant changes and 2 years is even better.

Unless you are meticulous in keeping maintenance records, put a sticker on the radiator showing the date of the last coolant change.

Use BMW coolant mixed 50:50 with distilled water. Tap water contains dissolved oxygen and may contain minerals that will use up the corrosion protection package and shorten the life of the coolant.

Even if you are changing the coolant on schedule it makes sense to periodically check the coolant with test strips and/or do a voltage check. When changing the coolant you must drain all of the coolant using radiator and block drains.

While it is best to top up the cooling system with coolant mix, adding at most a quart of distilled water between changes probably won’t cause any harm. So keep some coolant mix on hand.

From bmwdirtracer:

An electrical charge in your coolant as low as .15 volts destroys aluminum very quickly, and I’ve seen many cars with twice, even three times, that voltage in their cooling system.

This charge generally occurs because of old coolant which has lost its protection package and begins to swap ions with the aluminum and other metal components, causing the coolant to become an electrolyte, much like a battery, producing its own electrical charge as it eats the aluminum.

Set a good digital multimeter to DC voltage. If it is an auto-ranging type it will start on the lowest scale, but if not set the meter for the lowest voltage scale.

Attach the negative probe to the best ground – ideally, the battery negative post, although the main ground post underhood will do, in a pinch. Ground the positive lead of the multimeter, momentarily, to make sure the meter reads zero.

Then dip the positive probe of the meter into your coolant. If you see a voltage of 0.15 or above, it’s time to change your coolant.

6.Coolant Loss and Head Gasket Check

Obviously if you have coolant in the oil, oil in the coolant, or dense white smoke from the exhaust the head gasket has failed and the head is probably warped (and possibly cracked). But another case is a simple loss of coolant which could be caused by a leak in the cooling system or a head gasket problem.

A pressure test of the cooling system will tell if there are leaks and where they are. If the test is negative on a cold engine, repeat the test on a hot engine. Occasionally one will encounter a water pump that sporadically leaks while the car is being driven, but that will leave coolant residue on the front of the engine. When running the pressure check be sure to look under the car for fluid draining from the heater core

If testing and observation can’t find leaks, the loss of coolant will be from a head gasket leak that is pumping air into the cooling system. At some point the pressure will get high enough for the cap to lift to release the pressure, which will dump some coolant. That may only happen while the car is being driven and leave no evidence as to what happened.

The definitive test is to pressurize each cylinder for several minutes with 170-180psi while monitoring cooling system pressure with a 0-5psi gauge. A negative result on a cold engine requires the test to be repeated on a hot engine. But I have seen a couple of cases where this test didn’t work, but what follows did.

A DIY test for a leaking head gasket is to remove the cap to vent any pressure when the engine is completely cold (like after sitting overnight). With the cap back on the hoses will be soft. Drive the car for a bit (but don’t let it overheat) and let it completely cool down again. If the hoses are hard then, air is being pumped into the cooling system. An alternative test is to fully bleed the system, drive the car, and re-bleed. Release of a significant amount of air on a re-bleed (or subsequent re-bleed) is evidence of a head gasket leak.

From mhunter299928:

There is another method to test for head gasket failure. I think it’s called a block tester. Essentially it is a “turkey baster” with a chamber that you put a small amount of a chemical in. The chemical changes color in the presence of carbon monoxide. You put the device over the opening of the cooling system and suck some “air” through the chemical. If it changes color, you’ve got exhaust gas in your cooling system.

I’d like to add that a positive result of this test is evidence of a head gasket leak. But a negative result with other symptoms of a head gasket leak mean that further testing must be done.

From bmwdirtracer:

If and when a head gasket failure is confirmed, the cylinder head MUST go to a good machine shop, for crack testing and truing. If the head is cracked or overly warped, it may be irreparable.

If the engine involved is an aluminum block M54 or M52TUB, or M56, each head bolt should be released, and then retorqued to spec, before the head is removed, to find out whether the threads of the block are intact, as these threads often rip out, when the head warps on these engines..

7.Cooling System Bleed Procedure

The first part of this is applicable to earlier cars that don’t have an N series engine. See below for the N series engines.

1) Using ramps or a jack get the front of the car 1′ or more higher than the rear. That will make the radiator and bleed screw the highest point on the engine and facilitate removal of air.

2) With the bleed screw open, add coolant until no more air comes out of the bleed.

3) Leave the filler cap off, or at least loose, and set the heat for max temp and fan speed. Leaving the cap loose will prevent air that’s still in the system from causing a “coolant fountain” once the engine heats up. Start the engine and allow it to warm up to operating temp. As it warms up occasionally crack the bleed screw to release any air and top up the coolant as necessary.

4) Once the engine is at temp bring it up to 2000-2500rpm for a few seconds several times. Then crack the bleed until no more air is released. At this point the heater should be throwing lots of hot air, which indicates that the heater core is filled with coolant. You may have to repeat this a few times to get all the air out.

5) Drive the car a bit, allow it to cool back down, and recheck the bleed for air. Over the next few days you may get very small amounts (a few bubbles) of air out of the bleed screw.

A vacuum fill bleed system makes filling and bleeding the cooling system a trivial task. But the procedure above will work if you don’t have access to a vacuum fill system.. On an E30 and some other BMW’s you can speed up the fill process by removing the small hose that runs from the coolant reservoir to the top of the radiator at the radiator end. Then fill the reservoir to the mark, screw on the cap and blow into the hose until coolant comes out of the radiator nipple. That will fill the engine and radiator with coolant pretty quickly. It may take more than one fill/blow cycle to fill the radiator. Then bleed as per above to get any remaining air out.

Another method of filling the cooling system on M4x & M5x motors (from dworthy) is to gut a cap by removing the guts of the pressure release spring, ect., drill thru the cap, and install a valve stem. Once you fill up the radiator, to the top, apply about 10-15lbs of pressure to the cap and then open the bleeder valve on the radiator. This will push the coolant down and the air will come out thru the bleeder valve.

N series engines:

N-42/46 1.6-2.0l 4-cylinder (2002-2006) which are found in Europe have a mechanical pump, so the bleed procedure above will work. After 2006, they all went to the electrical water pump with the N-43/47 motor and it has the self bleed like the N-5x motors. The N-62 engine has a mechanical pump, so the above bleed procedure will work.

For N-series engines, which have an electric water pump:

Fill expansion tank about 8 ounces OVERFULL. Leave cap off.

Put a battery charger or professional battery maintainer on the vehicle, because electrical load is significant.

Turn on ignition.

Set heater to full hot, and HVAC fan to low.

Put throttle pedal on the floor for 15-20 seconds.

Get out, check that there is a stream of coolant flowing visibly in the neck of the expansion tank. If not, the bleed procedure has not been initiated; try again.

Check level in tank a couple of times in the first few minutes; allow level to reduce to “normal”, but not less than normal

After about 12 minutes, the stream will stop. Adjust level if necessary, and put cap on, and drive. You are done.

Also all the approved diagnostic computers can initiate this action.

8.Cooling System Flush

If the cooling system has been properly maintained and the coolant doesn’t look dirty, a flush is probably not necessary, A simple drain, refill, and bleed is all that is needed. Otherwise you might want to flush the cooling system. The older the car the greater the odds are that a flush will help.

1) Get the front of the car 1-2′ in the air on jack-stands.

2) Drain the coolant at the radiator and block, if possible remove the thermostat so you will have full flow through the cooling system even if the engine is not at normal operating temperature, and set the heater controls for full hot. You can’t do this on a later engine with the MAP controlled thermostat. O-ring sealed thermostats require you to make up a temporary gasket, which can be made out of pasteboard.

– hide quoted text –

3) Add flush compound and fill with plain water. Then run the engine at normal temperature as specified by the flush manufacturer (usually about 15 minutes at operating temperature). In cooler weather it may be necessary to block off some of the air into the radiator to decrease the warmup time.

4) Allow the engine to cool until you can place your hand on the cylinder head with out discomfort. Drain the system and refill with plain water.

5) Run the engine for 10-15 minutes or until temp is close to normal.

6) Repeat (4) and (5) until the water drained from the system is clear and free of debris.

7) Fill with coolant. Use BMW Blue coolant mixed 50:50 with distilled water. Tap water contains dissolved oxygen and may contain minerals. Either of which will reduce the lifetime of the coolant.

8) Then bleed the system

Notes:

You don’t absolutely need to remove the thermostat, but doing so will allow continuous flow through the radiator and will also make draining & filling faster and easier.

Always allow the engine to cool to the point that you can hold your hand on the cylinder head without discomfort. That will prevent scalds from hot coolant and prevent thermally shocking the head when you dump the coolant.

Filling the system with hot water makes the process go faster and keeps from having to run the engine a lot in a cold condition (rich mixture).

A few ounces of Cascade dishwashing detergent is a reasonable substitute for a commercial flush compound.

A rusty cooling system needs an oxalic acid flush. Kits for that (containing oxalic acid and soda for neutralizing the acid) used to be available, but aren’t now. Citric acid also works, but not as well on rust as oxalic acid. 6oz of oxalic acid and 4oz of soda will treat a 1-1/2 to 2-1/2 gallon cooling system. The procedure is like the above with an extra step 4 where the soda is added before the series of fill/drains are done. An engine that needs this treatment probably has a pretty severely clogged/damaged radiator and heater core, which strongly suggests that they be replaced after using this procedure on the cooling system. A cooling system that needs this treatment should have a detergent flush, the acid flush, then another detergent flush. The initial detergent flush will clean out any oil, which would interfere with the acid flush, and the final detergent flush helps to wash out loosened sediment.

Note that the cooling system should be replaced about every 100k. There are plastic and rubber parts in the cooling system that degrade with time and can suddenly fail. As can the water pump bearings & seal. If that happens on the highway and you don’t see the rise of the temp gauge in time serious engine damage can occur. Better to replace the system on schedule than to risk a failure. Replacing the cooling system means a new radiator, fan clutch, water pump, thermostat, reservoir, cap, and all hoses. If damaged or cracked, replace the fan.

The proper coolant is the BMW Blue coolant mixed 50:50 with distilled water. The dissolved oxygen and possible minerals in tap water will degrade the corrosion protection package in the coolant and shorten it’s life.

9.M Series Engine Cooling System Maintenance

The cooling system of a car with an M-series engine requires periodic replacement. The plastic and rubber bits degrade with time and can suddenly fail. If this happens and you don’t catch the movement of the temperature gauge needle quickly enough serious and expensive damage can be done to the engine.

As an FYI, the temperature gauge in most cars built since the early 90’s is heavily buffered and the needle will rest at the 12 o’clock position for engine temperatures between about 140F and 225F. Some cars, like the E-46 M3 have less buffering and indicate normal between about 170-200F. And on some cars (like the E46) the buffering can be changed by recoding. But in the general case as soon as the needle moves above the midpoint the engine is overheating. At which point you should immediately park the car and call for a tow.

Another warning sign of an impending overheat can be the battery light coming on. The alternator and water pump are driven by the same belt. If that belt breaks, the pump stops working and coolant no longer circulates. A quick check of the belt will tell if that has happened.

Replacement of the entire cooling system (radiator, expansion tank. cap, fan clutch, thermostat, water pump, and all hoses) should be done every 100k or 10 years whichever comes first. Sooner is better on V8 engine cars because the engine bay temperatures are higher. Failures have been seen as early as 60k.

From bmwdirtracer:

On M52TU and M54 engines there are two plastic tubes that run from the front of the cylinder head rearwards that must be replaced along with the rest of the cooling system. They break at the front, where the o-rings live, usually leaving the o-ring and a big chunk of plastic in the head. They cannot be removed without breaking them unless they are new. Replacing them requires removing the intake manifold.

The V8 M60/62 engines have stainless steel pipes from the water pump to the rear water manifold; those pipes have o-rings which should be replaced, If you are changing the water pump on these engines, and you allow the pipes to move forward when removing the water pump, then the intake manifold must be removed, and the rear water pipe o-rings replaced — or they WILL leak. Also, the M6x V8 engines have serious reliability issues with the valley pan, which holds coolant captive below it.

bmwdirtracer also thinks the thermostat and water pump on M5x series engines are 60-70k mile items.

From dworthy:

The M-42 and M-44 motor use a small plastic pipe down on the blocks that is used for the heater hoses, and CCV heating. Those plastic parts last about 15 years easily, and any overheat causes them to get brittle. So I think that 10 years is a bit excessive for changing them, as they should last much longer than that, unless the engine has been overheated.

Anything that upsets the air/fuel ratio can cause idle issues and misfires.

Probably the most common cause on cars with M-series engines include:

Intake leaks

A bad CCV

Injector or fuel delivery problems

Aged primary O2 sensors

The primary O2 sensors are a scheduled maintenance item. On OBD-I cars the interval is 60k, but on OBD-II cars the interval is 100k. It is best to use OE or OEM sensors meant for use on your car. An aged O2 sensor typically indicates a leaner condition that results in the DME increasing fuel trim to compensate for what it thinks is a lean condition. This is bad for fuel economy, can cause misfires, and the excess hydrocarbons in the exhaust can result in overheating of the catalytic converters, which can damage the converters.

dworthy has found a Bosch part finder that can help if people don’t want to pay for a dealership prices for oxygen sensors, cables, etc., that can be used it to verify that you have bought the right parts.

Leaking or dirty injectors or a problem with the fuel delivery system can result in a rich or lean condition. The rail fuel pressure can be checked and it is best to do this at idle and while driving.

You can check for a bad CCV by having a crank case pressure check run. The pressure in the crank case should be a vacuum or 3-6” of water as measured with a slack tube manometer. If the CCV is bad replace it and all associated hoses with OE or OEM parts.

The only reliable way to check for intake leaks is to have a smoke test run using a pro-type system that employs long persistence oil smoke.

Misfires on engines with coil over plug ignition can be caused by bad coils. After reading the codes to identify the affected cylinders, swap coils between cylinders with misfires and those without, after labeling them. If misfire follows the coil, replace coil. In a like manner a bad plug can be identified in the same way.

Another cause of misfires on engines with coil over plug ignition can be oil in the plug wells from leaking valve cover gaskets and/or grommets. The rubber boots at the bottom of the coils degrade with time and can cause misfires. Those can be replaced separately from the coils. And of course you must use the correct plugs for your engine.

Older engines with ignition wires and a distributor need those parts replaced about every 150k or 10 years. Those older engines, like the M20 or M30, need valve adjustments every 15k.

Misfires, like the primary O2 sensors, can result in excess hydrocarbons in the exhaust from unburnt fuel and can damage the catalytic converters.

10.Parking Brake Adjustment

A correct way to adjust the parking brakes on an M series engined car is:

1) Lower the hand brake and loosen the cable adjusters.

2) Working through a lug bolt hole turn the star adjuster with a flat-bladed screwdriver until the wheel locks. Turn the adjuster until it doesn’t want to turn any more. Then back off the adjuster 12 clicks. The book says 8 clicks, but I’ve had the shoes drag at that setting, so I use 12 clicks. Repeat for the other wheel. Note that the star adjuster is at the 6 o’clock position on later cars, but at the 10-11 o’clock position on an E30.

3) Raise and lower the hand brake several times to settle the cables. Then raise the lever two or three clicks and tighten the adjusters until the wheel can just be turned with moderate force.

If you have never had the rear rotors off, it would be a good idea to back the star adjusters all the way off and pull the rear rotors to see if the parking brake shoes are badly worn or if there are other problems in the parking brake mechanism.

In salt rich environments it isn’t unusual to find that the backing plates have rusted out where the compression pin locks into the backing plate and the shoes aren’t being held against the backing plate. The parts to fix this aren’t expensive, but the bearing hubs have to be removed to change the plates (which means new bearings). The fronts are pretty easy, but the rear hubs are a pain if you don’t have access to a Sir Tools B90 kit or similar.

From dworthy, an other method is:

The backing plates can be a PITA to replace, but I have cut them at the narrow where the brake caliper sits, then bend them slightly to get around the hub. Now you can weld the plate back together or just leave it, as it won’t really make much of a difference.

How I adjust the parking brake:

1. Remove all the slack from up front.

2. Tighten the star wheel until it locks the wheel.

3. Loosen 2 clicks, and listen. There should be a slight dragging sound coming from the pads.

4. Tighten the cable up to where the nut is just touching the handle.

5. Move the handle up and down to remove any slack.

6. Check the nut again, see if any slack is left in the cable.

7. Pull up, you should be able to raise it 5-7 clicks before it gets really tight.

8. Drop the handle, and raise back up 2 clicks and check the wheels.

9. There should be a good amount of resistance in the rear wheels when trying to turn them.

As a rule of thumb, when I replace the rear disks, I also do the parking brake shoes, as they are cheap and I have seen too many of them with frozen springs, etc., due to lack of use.

The F-3x 3er is similar to the E-series cars. The only difference is the single nut at the handle instead of one for each side. In the rear, you have the adjuster at the 12 o’clock position.

None of this applies to cars with a parking brake button or have the parking brake operation integrated into the transmission shifter rather than a parking brake lever as they have a different parking brake system.

Ps. Special thanks to

thejlevie

bmwdirtracer

dworthy

mhunter29928

ptardi

White94RX

Save

Save

Save

- US$479.00 / piece

- US$109.00 / piece

- US$7.99 / piece

- US$19.99 / piece

- US$55.99 / piece

- US$68.00 / piece

- US$66.00 / piece

- US$15.00 / piece

- US$349.00 / piece

- US$209.00 / piece

- US$19.99 / piece

- US$34.99 / piece